Rigging components must have a to 1 safety factor – Rigging components, the unsung heroes of countless industries, play a critical role in ensuring safety and efficiency. At the heart of their design lies a fundamental principle: the 1:1 safety factor. This ratio serves as an indispensable safeguard, ensuring that rigging components can withstand the rigors of their intended applications.

The safety factor, a cornerstone of rigging component design, represents the ratio between the component’s breaking strength and its working load limit. By maintaining a 1:1 safety factor, engineers ensure that rigging components can safely bear loads equal to their rated capacities, providing a crucial margin of error in real-world scenarios.

Rigging Components Must Have a 1 to 1 Safety Factor: Rigging Components Must Have A To 1 Safety Factor

Rigging components are essential for lifting and moving heavy loads safely and efficiently. To ensure the safety of these operations, it is crucial that rigging components have a safety factor of at least 1 to 1.

A safety factor is a ratio that compares the ultimate strength of a component to the maximum load it is expected to encounter. A safety factor of 1 to 1 means that the component will fail if it is subjected to a load equal to its ultimate strength.

There are several factors that can affect the safety factor of a rigging component, including the material it is made of, its dimensions, and the manufacturing process used to create it.

Safety Factor Considerations

The purpose of a safety factor is to provide a margin of error in the event that a rigging component is subjected to a load that is greater than expected.

There are several factors that can affect the safety factor of a rigging component, including:

- The material the component is made of

- The dimensions of the component

- The manufacturing process used to create the component

- The condition of the component

- The environment in which the component is used

It is important to consider all of these factors when selecting rigging components for a particular application.

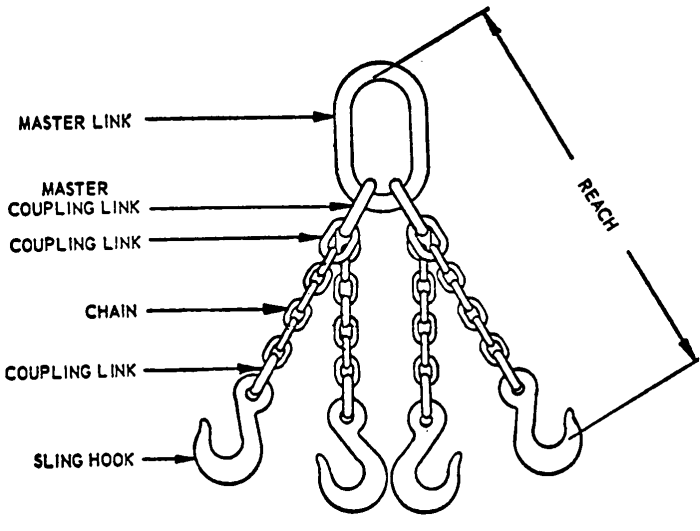

Design Requirements, Rigging components must have a to 1 safety factor

Rigging components must be designed to meet specific requirements in order to achieve a safety factor of 1 to 1.

These requirements include:

- The component must be made of a material that has a high strength-to-weight ratio.

- The component must have dimensions that are appropriate for the load it is expected to bear.

- The component must be manufactured using a process that ensures its integrity.

By meeting these requirements, rigging components can be designed to have a safety factor of 1 to 1, which will ensure their safe and reliable operation.

Inspection and Maintenance

Regular inspection and maintenance are essential to ensure the safety and integrity of rigging components.

Inspections should be performed by a qualified inspector on a regular basis, and more frequently if the component is used in a harsh environment or for heavy lifting.

Inspections should include a visual examination of the component for any signs of damage, such as cracks, corrosion, or deformation.

Maintenance should be performed as needed to keep the component in good working condition.

Standards and Regulations

There are a number of industry standards and regulations that govern the design, manufacture, and use of rigging components.

These standards and regulations are in place to ensure the safety of workers and the public.

It is important to be aware of these standards and regulations and to comply with them when using rigging components.

Best Practices

There are a number of best practices that can be followed to ensure the safe and efficient use of rigging components.

These best practices include:

- Using rigging components that are designed for the specific application

- Inspecting rigging components regularly for any signs of damage

- Maintaining rigging components in good working condition

- Storing rigging components properly

- Training workers on the safe use of rigging components

By following these best practices, you can help to ensure the safety of your workers and the public.

FAQ Section

What is the purpose of the 1:1 safety factor in rigging components?

The 1:1 safety factor ensures that rigging components can safely withstand loads equal to their rated capacities, providing a margin of error in real-world scenarios.

What factors can affect the safety factor of a rigging component?

Factors that can affect the safety factor include the material properties, component dimensions, manufacturing processes, and environmental conditions.

What are some examples of design features that contribute to a safe and reliable rigging component?

Design features that contribute to safety include the use of high-strength materials, robust construction, and corrosion-resistant coatings.